News

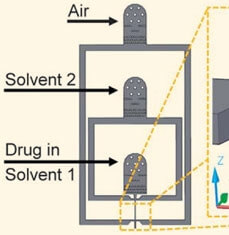

Two flow-focusing streams for drug formulations and a third for compressed air to form a spray generate particle sizes below 100nm, increasing the drugs' solubility.

Teams from the US and Germany have developed a spray drying technique to fabricate drug formulations smaller than 100nm for pharmaceutical trials, improving the drugs' solubility, or bioavailability.

Over the last decade, the molecular complexity of drugs has increased significantly, leading to poor solubility, which means that the compounds can't be used in the human body. To determine if new formulations have potential as successful drugs, solubility tests are run at an early stage of development. However, the amount of drug available for these tests is usually very small.

One way to get around this problem is by decreasing the compounds' particle size. David Weitz from Harvard University, Cambridge, US, and colleagues, have done just that by developing a microfluidic device made from poly(dimethylsiloxane), incorporating two flow-focusing streams and a third for compressed air to form a spray, that can generate particle sizes below 100nm.

"We were searching for convenient ways of creating drug nanoparticles to increase the bioavailability. Rapid precipitation from solution through addition of a poor solvent is a simple means of making small particles,but they tend to coarsen and become larger than the desired nanometre size," explains Weitz. "To prevent this, we wanted to remove them from the solvent as quickly as possible and we thought that drying the solvent would be a way to do so."

Topics: Bioengineering, Applied Physics

Cutting-edge science delivered direct to your inbox.

Join the Harvard SEAS mailing list.

Scientist Profiles

David A. Weitz

Mallinckrodt Professor of Physics and of Applied Physics