The building blocks of a better battery

The smartphone in your pocket is a treasure-trove of technological innovations, from the fingerprint scanner used for login to the organic light-emitting diode that illuminates the screen. However, one critical piece of smartphone technology hasn’t had much of an upgrade since it was commercialized in 1991—the rechargeable lithium ion battery that powers the device.

Qichao Hu, Ph.D. ’12, an applied physics graduate from the Harvard John A. Paulson School of Engineering and Applied Sciences (SEAS), established a company that develops and supplies a new technology that could revolutionize the rechargeable batteries that power smartphones and many other high-tech products. The technique he pioneered makes volatile lithium metal batteries, which have twice the energy capacity as their lithium ion cousins, safe and effective for everyday use.

Hu, who launched the startup SolidEnergy Systems in 2012, developed this innovation while he was a postdoctoral fellow at MIT. He and his lab mates were working on a solid-state lithium metal battery, but the team kept running into one major problem.

“The battery had a really high energy density, but it couldn’t function at room temperature,” he recalled.

The solution, Hu discovered, was in the electrolyte.

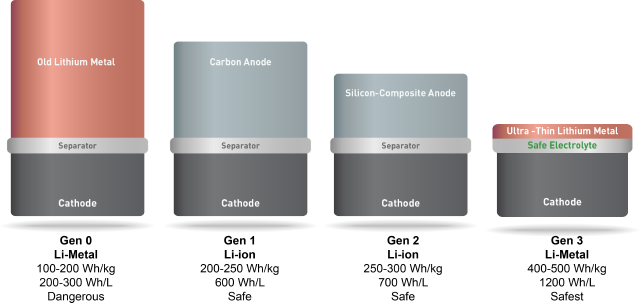

Lithium batteries are made of four primary components, the anode, cathode, separator, and electrolyte. The anode and cathode are typically metal oxide or metal materials that store lithium ions, the separator is a permeable membrane that physically separates the cathode and anode while allowing lithium ions through, and the electrolyte is a chemical that enables the flow of lithium ions between the cathode and anode. A solid-state lithium metal battery uses high-energy lithium metal foil for the anode, which can hold more ions, and therefore more energy, than the typical carbon or silicon composite anode material.

The new type of dual-layer electrolyte Hu and his collaborators developed has a very high conductivity at room temperature, enabling the solid-state lithium metal battery to function safely and effectively in commercial devices. And by utilizing that electrolyte in conjunction with an extremely thin lithium metal anode, they were able to produce a cell that is nearly anode-free, greatly reducing the battery size and weight.

This chart shows how SolidEnergy Systems is able to produce rechargeable lithium metal batteries that are smaller and more energy-dense than those currently on the market. (Image provided by Qichao Hu.)

To further develop this innovation, Hu launched the startup in 2012, which turned out to be one of the worst years for clean tech in recent memory. Lithium ion battery maker Ener1 declared bankruptcy in January of that year, while the Waltham, Mass., firm A123 Systems, which had been producing rechargeable automobile batteries for Tesla, followed suit in October.

“That was a stressful time in clean tech, but those bankruptcies ended up being a good thing for our company. We were able to move into the space vacated by A123 and use their facility as an incubator to further develop our technology. It saved us a lot of learning curve in time and capital and allowed us to get things done super fast,” he said.

Only a few months later, the firm raised its first round of investment and by 2015, Hu and his team had developed a working prototype that doubled the energy density of the best lithium ion batteries. After raising a second round of funding, the company moved into its own state-of-the-art pilot production facility in Woburn, Mass.

The SolidEnergy Systems production facility in Woburn, Mass. (Photo provided by Qichao Hu.)

The firm’s business model is key to its stability in the volatile clean tech market, Hu explained. SolidEnergy Systems is not a large-scale battery manufacturer; it is a battery solution provider. The company supplies battery makers with the core materials and manufacturing process technology that can be seamlessly integrated into current rechargeable battery production infrastructure.

“Battery technology development is slow because the testing cycle takes a very long time, and there is a lot of noise. Because it takes a long time to see a real product, often people use that as an excuse not to deliver real results,” he said. “Our company takes a much more practical and commercial approach. We think about final batteries like our customers, and focus on real results. The way we have been attracting so many great investors and customers wasn’t because we sent them slides or gave good keynotes, we simply sent them real cells to test.”

The company plans to launch this product first into drones and then consumer electronics, including watches and phones, and ultimately electric cars.

“One piece of solving the problem of air pollution and environmental degradation involves cleaner transportation, and a key part of that puzzle is the battery,” he said. “Electric cars have not really taken off yet because of battery limitations—they simply don’t drive far enough on a single charge. Our technology can fundamentally solve that problem.”

Lightweight, longer-lasting batteries could also have applications in many projects that have an element of social good. For example, they could be used in long-range high-altitude drones to provide wireless Internet access to remote regions of developing countries.

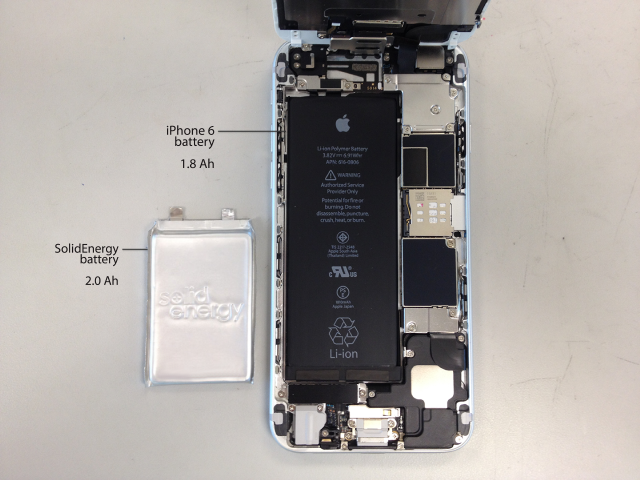

This photo shows the size difference between an iPhone battery and a battery produced using the technique pioneered by Qichao Hu and SolidEnergy Systems. (Photo provided by Qichao Hu.)