News

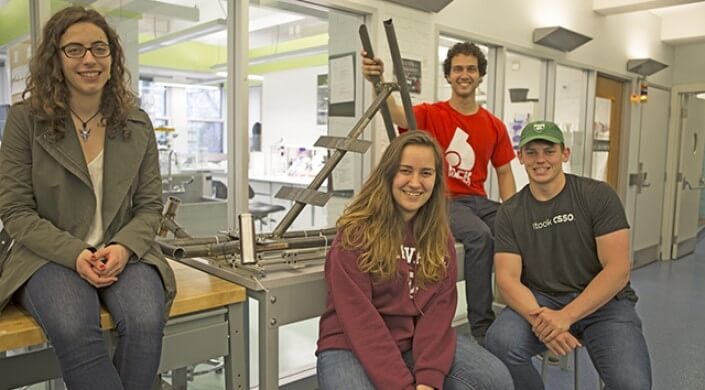

Human Powered Vehicle Team members Andrea Rodriguez-Marin Freudmann, Rainy Michelsen, Alex Giglio, and Gunnar Allison, pose with the chassis for their nearly completed recumbent-style tadpole trike. (Photo by Adam Zewe/SEAS Communications)

While the phrase ‘innovative transportation’ may bring to mind self-driving cars or hyperloop tubes, novel human-powered vehicles stand to make a significant impact towards improving future transportation efficiency and sustainability.

But a truly avant-garde human-powered vehicle is far from the 18-speed Huffy bicycle many remember using to zip around town during their youth.

Developing a creative, safe, and efficient vehicle was the aim of the newest student club at the Harvard John A. Paulson School of Engineering and Applied Sciences (SEAS), the Human Powered Vehicle Team. They put their design and fabrication skills to the test to create a road-ready vehicle from scratch.

“This is a different kind of project. It is very mechanical and it is scaled up, with a different perspective on what your goals are,” said Andrea Rodriguez-Marin Freudmann, S.B. ’20, a mechanical engineering concentrator. “The little robots we build in a lot of our classes aren’t going to hurt anyone. But for this project, we had to consider how our design would affect people in the real world.”

The team's completed recumbant-style tadpole trike enables a rider to reach speeds of 30 miles per hour. (Photo provided by the SEAS Human Powered Vehicle Team)

The students developed a recumbent-style tadpole trike—a steel-framed vehicle with one back wheel and two front steering wheels. The trike’s intricate gearing and drive train system enable a rider to reach speeds of 30 miles per hour, while exerting significantly less effort than an upright bike would require. The vehicle also provides storage behind the seat, making it a more viable option for a commuter seeking environmentally friendly transportation.

Safety was a major focus of the team’s design. The students developed a roll-bar system to protect the rider in the event of a collision or rollover, and they incorporated a double-bar system into the trike’s backbone design to provide a higher level of stability.

“We are trying to build something that is sustainable for a city commuter. Regular bikes are pretty fast if you know how to ride them, but if you bump into a car, you could easily be seriously injured,” said Alex Giglio, S.B. ’20, a mechanical engineering concentrator. “But if you ride in something like our design, with a full roll-bar protection system, your chances of surviving a collision are much greater. I think this is much more attractive for the urban commuter, who is sharing the streets with cars.”

As the team designed and built the trike, they had to learn new fabrication skills that aren’t commonly taught in most core engineering classes, such as welding. They were also immersed in a new community of bikers and human powered vehicle enthusiasts, spending time pouring over documentation and designs that were often very different from projects they had encountered in their coursework.

Team members prepare to weld pieces of the vehicle's chassis. (Photo provided by the SEAS Human Powered Vehicle Team)

Collaboration and effective team dynamics (as well as good senses of humor) proved invaluable as they painstakingly created each piece of the frame, often working late into the night in the Active Learning Labs.

“Every decision in the process cascades. If we are going to make a change in the frame, that affects the steering, it affects what the drive train looks like, it affects how the seat will be adjusted,” said Gunnar Allison, S.B. ’20, a mechanical engineering concentrator. “Having every team member communicate their ideas with one another during the design process is pivotal.”

The team attended the American Society of Mechanical Engineers Human Powered Vehicle Challenge in April. They chose not to race their trike in this year’s competition, which included a drag race and an endurance race portion, because of welding errors that raised safety concerns. Even without racing, the team scored enough points from their design to earn 38th place among the 47 teams in the competition.

Team members learned many valuable lessons they will put into practice next year, when they hope to design and build a new ready-to-race vehicle.

“I learned a great deal about our responsibility as mechanical engineers, and that we are supposed to be of service to humanity. We are building things within a larger social context,” said Rainy Michelsen, S.B. ’20, a mechanical engineering concentrator. “Even though this project was not easy, it was not impossible, either. Being able to face and overcome the many challenges was very rewarding.”

Good senses of humor proved to be instrumental as members of the Human Powered Vehicle Team worked long hours in the Active Learning Labs on the chassis. (Photo provided by the SEAS Human Powered Vehicle Team)

Join the Human Powered Vehicle Team

The Human Powered Vehicle Team is seeking students of any concentration to join next year’s team. There is no comp process and no previous experience is required. Interested students are asked to contact harvardhpvt@gmail.com for more information.

Join the Human Powered Vehicle Team

The Human Powered Vehicle Team is seeking students of any concentration to join next year’s team. There is no comp process and no previous experience is required. Interested students are asked to contact harvardhpvt@gmail.com for more information.

Topics: Student Organizations

Cutting-edge science delivered direct to your inbox.

Join the Harvard SEAS mailing list.

Press Contact

Adam Zewe | 617-496-5878 | azewe@seas.harvard.edu