Engineering Design Projects (ES 100), the capstone course at the Harvard John A. Paulson School of Engineering and Applied Sciences, challenges seniors to engineer a creative solution to a real-world problem.

Concept Design and Model of Actuated Tail for Active Pitch Angle Control in HAMR

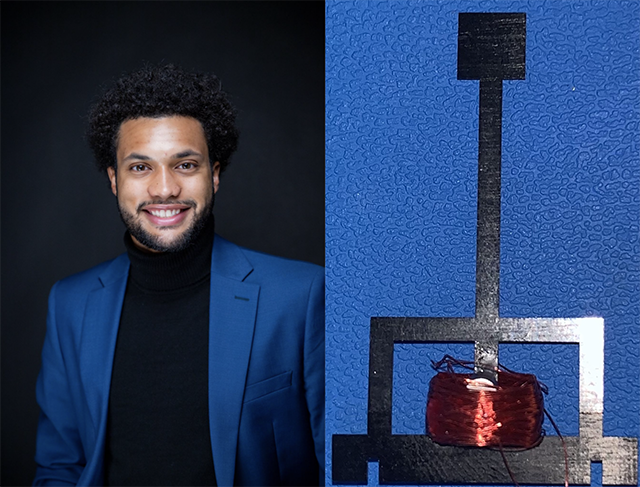

Kahlil Wassell, S.B. ’21, mechanical engineering

Please give a brief summary of your project.

This project focused on creating an actuated appendage for the microrobot HAMR (Harvard Ambulatory Microrobot) that would allow it better to traverse bumps in its environment, as well as providing other auxiliary opportunities for remote sensing

What was the inspiration for this project?

The inspiration from this project came from the fact that variable terrains are something the HAMR platform struggles with during its normal operation and will be critical to its successes in future endeavors where it will need to navigate uncontrolled environments. This appendage could also have other uses, including increasing HAMR's ability to sense its environment with the attachment of various sensors.

How will this project help solve the problem you identified?

By adding an actuated tail to the HAMR, it should better allow it to control the location of its center of mass, and through a dynamic motion adjust its pitch angle. This would better allow HAMR to get its legs above obstacles that are in its way, but lie above its current step height.

What were the biggest challenges of this project?

The biggest challenge with this project was the scale. HAMR is on the centimeter to millimeter scale, and thus designing an actuator for the platform that was both lightweight and small was a significant challenge. Understanding the manufacturing techniques used to create HAMR was also a considerable challenge, as the process is quite intricate and involves many steps.

What did you learn through this experience?

From this experience, I gained multiple technical and organizational skills. Creating a whole project from the ground up with your own deadlines and with little knowledge of what issues would arise was challenging and taught me a lot about the design process and how to adjust for unforeseen roadblocks. In addition, I obtained more insight into the technical design process and am grateful to have learned a lot about the manufacturing process that is used on many of the cutting-edge microrobots that are created in the Harvard Microrobotics Laboratory. I now have a much better understanding of the roadblocks that can occur using this manufacturing method.

Press Contact

Adam Zewe | 617-496-5878 | azewe@seas.harvard.edu