For a senior capstone project, Ben Schroeder designed a robotic hand attachment for spacesuits

Engineering Design Projects (ES 100), the capstone course at the Harvard John A. Paulson School of Engineering and Applied Sciences (SEAS), challenges seniors to engineer a creative solution to a real-world problem.

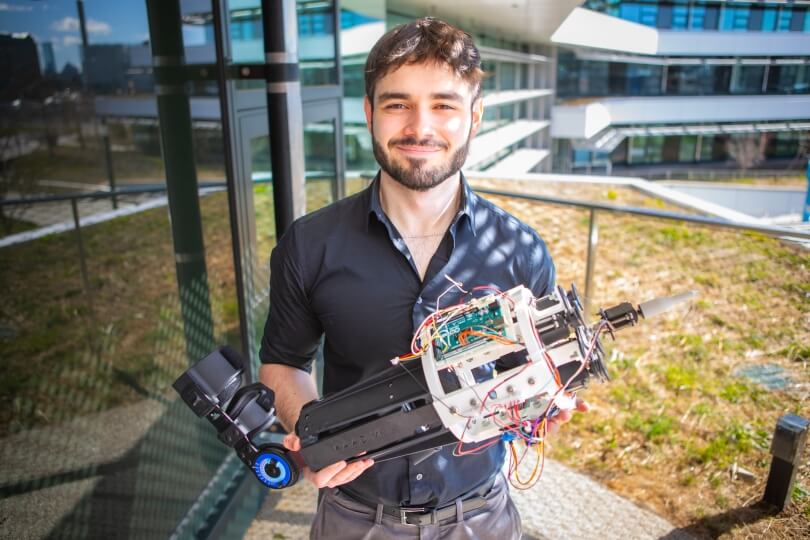

Robotic Assistance for Astronaut Dexterity (RAAD)

Ben Schroeder, S.B. '24, Mechanical Engineering

Advisor: Rob Howe

Please give a brief summary of your project.

RAAD is a robotic hand/wrist meant to attach to spacesuits for astronauts to use during extravehicular activities, or spacewalks. The gloves worn on spacesuits are thick and stiff, which fatigue and injure astronauts as they use their hands across a seven-hour space walk. Instead of a glove, astronauts wear RAAD as a pressurized chamber in which their hand can sit unencumbered. From there they control a robotic hand to perform tasks remotely without the fatigue imposed by a suit glove.

How did you come up with this idea for your final project?

I've been interested in crewed spaceflight and how to design aerospace technology around the needs of humans. The use of our hands is so fundamental, I was astonished that the current solutions are still so limiting, if not harmful, to the astronauts.

Is there a real-world challenge that this project addresses?

Spacesuit gloves are designed to protect the astronaut's hands from the inhospitable conditions of space. However, current solutions are focused on how to make an existing glove design inhibit the hand as little as possible. RAAD entirely abandons the traditional form factor of a glove, replacing the hand's direct functionality with robotics.

What was the timeline of your project?

I came up with the concept of RAAD near the end of the spring of my junior year, and spent time during my internship at SpaceX talking to experts in spacesuits and human-interfacing hardware design to better understand how to design for astronauts. I then spent the fall working on technical specifications and preliminary design. January through March was dedicated to prototyping, construction, and testing.

What part of the project proved the most challenging?

Rather than one specific challenge, I think the most challenging component of the project was the number of different subsystems that had to work in concert to form a cohesive final product. RAAD includes a robotic wrist, multiple tools, off-the-shelf components, printed structural elements, inertial sensors, servo motors, all within one assembly.

What part of the project did you enjoy the most

While it represented the most intensive work throughout the project, the prototyping and building phase felt the most exciting. It was deeply gratifying to see models and ideas that existed only on a computer or in my brain slowly manifest physically before me. While design has its own level of creativity and excitement, there is a visceral joy to holding something you've made in your hands.

What did you learn, or skills did you gain, through this project?

It sounds cliché, but a major goal of this project was to push myself out of my fields of comfort that my past engineering experience had afforded me. Much of my academic and professional experience in engineering has dealt in structural loads and thermodynamics. I chose a robotics project specifically because I knew it would demand a level of confidence in electrical systems, software, and moving mechanisms that I didn't have going in. RAAD's human-interfacing nature also gave me the opportunity to learn how to conform hardware to the human body, measure human factors (such as fatigue or dexterity), and mimic bodily movements through robotics. In this sense, I got to step outside the structures world and play as an electrical engineer, software developer, bioengineer, and roboticist for this project. Not only did that experience increase my confidence in those specific fields, it affirmed for me that labels I put on myself as a "certain type" of engineer are artificial and self-imposed.

Press Contact

Matt Goisman | mgoisman@g.harvard.edu