News

The pads of geckos’ notoriously sticky feet are covered with setae – microscopic, hairlike structures whose chemical and physical composition and high flexibility allow the lizard to grip walls and ceilings with ease. Scientists have tried to replicate such dynamic microstructures in the lab with a variety of materials, including liquid crystal elastomers (LCEs), which are rubbery networks with attached liquid crystalline groups that dictate the directions in which the LCEs can move and stretch. So far, synthetic LCEs have mostly been able to deform in only one or two dimensions, limiting the structures’ ability to move throughout space and take on different shapes.

Now, a group of scientists from the John A. Paulson School of Engineering and Applied Sciences (SEAS) and Harvard’s Wyss Institute for Biologically Inspired Engineering has harnessed magnetic fields to control the molecular structure of LCEs and create microscopic three-dimensional polymer shapes that can be programmed to move in any direction in response to multiple types of stimuli. The work, reported in PNAS, could lead to the creation of a number of useful devices, including solar panels that turn to follow the sun for improved energy capture.

“What’s critical about this project is that we are able to control the molecular structure by aligning liquid crystals in an arbitrary direction in 3D space, allowing us to program nearly any shape into the geometry of the material itself,” said first author Yuxing Yao, a graduate student in the lab of Joanna Aizenberg, the Amy Smith Berylson Professor of Material Science at SEAS and Wyss Founding Core Faculty Member.

The microstructures created by Yao and Aizenberg’s team are made of LCEs cast into arbitrary shapes that can deform in response to heat, light, and humidity, and whose specific reconfiguration is controlled by their own chemical and material properties. The researchers found that by exposing the LCE precursors to a magnetic field while they were being synthesized, all the liquid crystalline elements inside the LCEs lined up along the magnetic field and retained this molecular alignment after the polymer solidified. By varying the direction of the magnetic field during this process, the scientists could dictate how the resulting LCE shapes would deform when heated to a temperature that disrupted the orientation of their liquid crystalline structures. When returned to ambient temperature, the deformed structures resumed their initial, internally oriented shape.

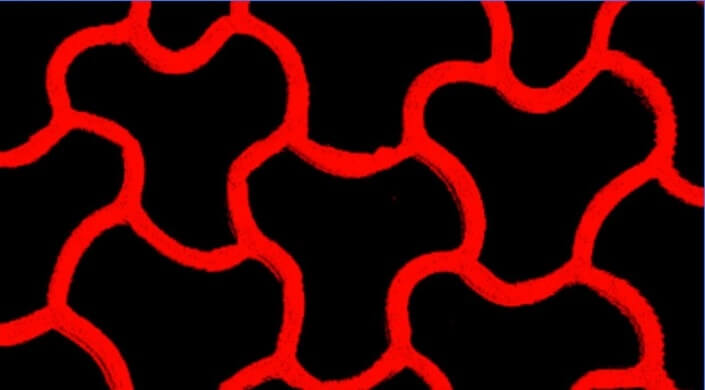

Micropillars made of light-responsive liquid crystal elastomer (LCE) change direction to "follow" light when illuminated from different directions, which could lead to more efficient solar panels. Credit: Wyss Institute at Harvard University

Such programmed shape changes could be used to create encrypted messages that are only revealed when heated to a specific temperature, actuators for tiny soft robots, or adhesive materials whose stickiness can be switched on and off. The system can also cause shapes to autonomously bend in directions that would usually require the input of some energy to achieve. For example, an LCE plate was shown to not only undergo “traditional” out-of-plane bending, but also in-plane bending or twisting, elongation, and contraction. Additionally, unique motions could be achieved by exposing different regions of an LCE structure to multiple magnetic fields during polymerization, which then deformed in different directions when heated.

The team was also able to program their LCE shapes to reconfigure themselves in response to light by incorporating light-sensitive cross-linking molecules into the structure during polymerization. Then, when the structure was illuminated from a certain direction, the side facing the light contracted, causing the entire shape to bend toward the light. This type of self-regulated motion allows LCEs to deform in response to their environment and continuously reorient themselves to autonomously follow the light.

Micropillars made of light-responsive liquid crystal elastomer (LCE) change direction to "follow" light when illuminated from different directions, which could lead to more efficient solar panels. Credit: Wyss Institute at Harvard University

Additionally, LCEs can be created with both heat- and light-responsive properties, such that a single-material structure is now capable of multiple forms of movement and response mechanisms.

One exciting application of these multiresponsive LCEs is the creation of solar panels covered with microstructures that turn to follow the sun as it moves across the sky like a sunflower, thus resulting in more efficient light capture. The technology could also form the basis of autonomous source-following radios, multilevel encryption, sensors, and smart buildings.

“Our lab currently has several ongoing projects in which we’re working on controlling the chemistry of these LCEs to enable unique, previously unseen deformation behaviors, as we believe these dynamic bioinspired structures have the potential to find use in a number of fields,” said Aizenberg.

Additional authors of the paper include James Waters, and Anna Balazs, from the University of Pittsburgh; Anna Schneidman, Jiaxi Cui, Xioguang Wang, and Nikolaj Mandzberg from Harvard SEAS, and Shucong Li from Harvard’s Chemistry department.

This research was supported by the Department of Energy and DARPA.

Joanna Aizenberg honored by Advanced Materials

Materials scientist featured in journal’s Hall of Fame

Aizenberg has been named a laureate of the Advanced Materials Hall of Fame.

Laureates are chosen for their impact on the field of materials science by the editors of Advanced Materials.

Aizenberg was honored for her leading influence on the field of materials science and for her pioneering work in bio-inspired materials. In addition to being recognized as a leader in the field of materials science research, Aizenberg is also a longstanding board member of Advanced Materials. “Learning from Nature's concepts not only satisfies our curiosity for understanding the world around us, but also promises to drive a paradigm shift in modern materials science and technology”, Aizenberg believes.

Aizenberg is also a Core Member of the Wyss Institute for Biologically Inspired Engineering at Harvard University and the Director of the Kavli Institute for Bionano Science and Technology.

As a Hall of Fame laureate, Aizenberg was invited to submit an article to the Hall of Fame virtual issue of Advanced Materials.

Read Aizenberg’s Hall of Fame profile in Advanced Science News.

Topics: Materials

Cutting-edge science delivered direct to your inbox.

Join the Harvard SEAS mailing list.

Scientist Profiles

Joanna Aizenberg

Amy Smith Berylson Professor of Materials Science and Professor of Chemistry & Chemical Biology

Press Contact

Leah Burrows | 617-496-1351 | lburrows@seas.harvard.edu