News

Key Takeaways

-

Harvard SEAS researchers developed a method to program kirigami surfaces by embedding multiple levels of cuts, enabling more complex and controlled mechanical responses.

-

The technique allows kirigami materials to reveal intricate shapes or messages when stretched, demonstrating precision in both form and function.

-

Potential applications include stretchable electronics, wearable devices, soft robotics, smart displays, and adaptive surfaces that can change properties like friction.

Kirigami, the Japanese art of paper cutting, has already been used to transform 2D shapes into 3D shapes, turn squares into circles and even propel a snake-like robot across Harvard’s campus. But researchers have just scratched the surface of what this technique can do.

Now, researchers at the Harvard John A. Paulson School of Engineering and Applied Sciences (SEAS) have developed a way to program kirigami surfaces with complex information, expanding the design possibilities of kirigami structures and enabling even more applications for kirigami materials.

The research was published in Advanced Functional Materials.

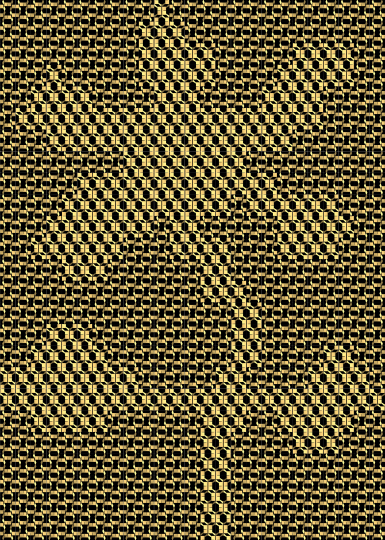

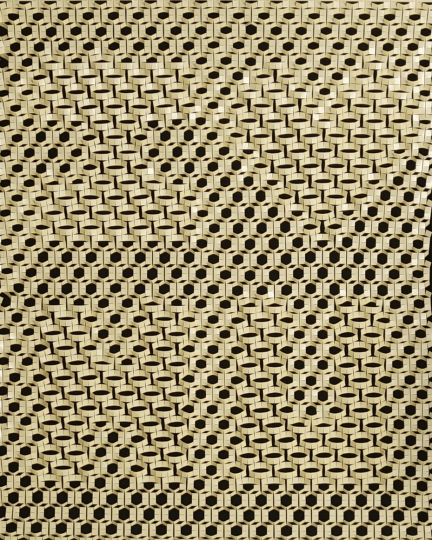

To increase the functionality of kirigami materials, the researchers took a hierarchical approach, meaning they embedded different levels of cuts in the materials.

“Essentially, we initially divided the sheet into a series of square shapes via laser cutting. Then, we further subdivide the squares into smaller squares using another level of cuts,” said August G. Domel, a former graduate student at SEAS and co-first author of the paper. “When the material is stretched, the initial level of cuts respond, but then the second level of cuts add a much richer possible set of responses.”

By carefully choosing the thickness of the sheets and the width of the cuts associated with each level, the researchers found that a material could be programmed to perform in specific ways. To demonstrate their technique, they programmed kirigami sheets to reveal complex shapes when stretched, including a Christmas tree and a message that reads “I Love HU”.

“This increased control over the mechanical properties of the material means that kirigami surfaces could be integrated into soft robotic materials to create tactile sensors and stretchable electronics, smart displays or even skins that can change their level of friction based on the environment,” said Katia Bertoldi, the William and Ami Kuan Danoff Professor of Applied Mechanics at SEAS and senior author of the study.

The research was co-authored by Ning An, Jinxiong Zhou and Ahmad Rafsanjani. It was supported by the China Scholarship Council, the National Natural Science Foundation of China Grants, the Swiss National Science Foundation and the National Science Foundation.

Kirigami-inspired research developments

Follow the evolution of kirigami-inspired research at Harvard SEAS at this link.

Topics: Kirigami, Materials, Materials Science & Mechanical Engineering, Research, Robotics

Cutting-edge science delivered direct to your inbox.

Join the Harvard SEAS mailing list.

Scientist Profiles

Katia Bertoldi

William and Ami Kuan Danoff Professor of Applied Mechanics

Press Contact

Leah Burrows | 617-496-1351 | lburrows@seas.harvard.edu